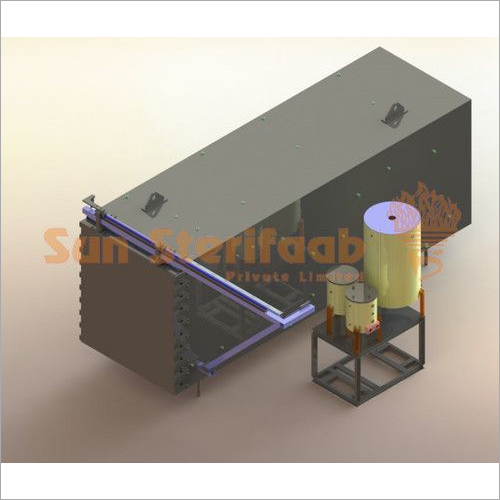

Industrial ETO Sterilizer

1250000 INR

Product Details:

- Material Stainless Steel,Mild Steel

- Product Type Industrial Ethylene Oxide Sterilizer

- Usage In many industries to control temperature, moisture, gas injection, gas exposure and all critical time and pressure based parameters

- Type Gas Sterilization Equipments

- Insulation Triple Wall

- Click to view more

X

Industrial ETO Sterilizer Price and Quantity

- 1 Unit

- 1250000 INR

Industrial ETO Sterilizer Specification

- Gas Sterilization Equipments

- Industrial Ethylene Oxide Sterilizer

- In many industries to control temperature, moisture, gas injection, gas exposure and all critical time and pressure based parameters

- Stainless Steel,Mild Steel

- Triple Wall

Industrial ETO Sterilizer Trade Information

- Nhava Sheva

- Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- 10 Unit Per Month

- 6 Week

- Middle East, Africa, Asia

- All India

- ISO, CE & OHSAS, ISO 9001 2008,WHO Certificate,

Product Description

Door: There are auto door ans double door models are for clean room applications.

Low cost per cycle: Lowest operating costs in comparison to other options.

Benefits of ETO sterilizer Superior Automation:

Low cost per cycle: Lowest operating costs in comparison to other options.

Benefits of ETO sterilizer Superior Automation:

- Automated system with advanced SCADA software to remotely control and monitor all possible cycle parameters

- A Microprocessor / PLC controls gas injection, gas exposure, temperature, moisture and all important time and pressure based parameters during sterilization

- Essential sterilization parameters, such as Current Values, Phase Status, and Set values are continuously displayed at all times on Controller Screen & on Remote Computer by SCADA software

- Continuous display of pressure, temperature and humidity gives Cycle status to the users at all times

- Temperature to within plus minus 3 degree centigrade of the Set Sterilization temperature is maintained in the chamber, uniformly and accurately

- Error code and alarm are generated and cycle automatically stops in case of any error. Computer Screen shows error and possible cause as well as remedy

- The advanced SCADA software provided stores detailed records of Process-Data for every cycle

- Reports are available in Data, Summary and Graph formats for every batch of goods sterilized

- User can re-print reports making use of any printer

- Digital storage of data reduces cost and space, as well as ensures safety of data. It also eliminates the cost of expensive thermal printing

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Get a Quote

Get a Quote

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free